| Category |

British and German stocks across the network seem to be set |

Gold black air duct hard wrap |

Metal duct soft cladding |

| Install |

Integrated installation, less process, convenient installation and high efficiency |

Requires two installations and construction, and the construction period is long |

High labor cost and long construction period |

| Quality |

The machine is integrated in the factory, and it is easy to assemble and install on site

hrough connectors, and the quality is guaranteed. |

The self-weight is relatively heavy, and the requirements for the fireproof board and the

boom of the wafer are high. |

Manual operation, there are many uncertain factors on site, appearance five: |

| Service life |

ater and moisture resistance, anti-corrosion, aging resistance, non-returning,

without external damage, the normal service life can reach more than 50 years |

In the wet environment of metal air duct, the base corrodes, and the variable increases

after the rock absorbs moisture, which reduces the service life, and the service life is only about 5-10 years |

The base corrosion service life of metal air ducts in a humid environment is only about 5-10 years |

| Other |

Net weight 25mm, save machine space |

The thickness is 60mm, occupying the floor space |

The thickness is 50mm, the surface temperature effect is not good |

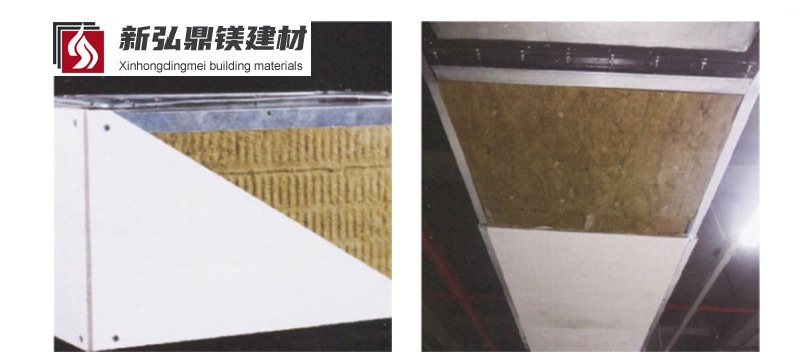

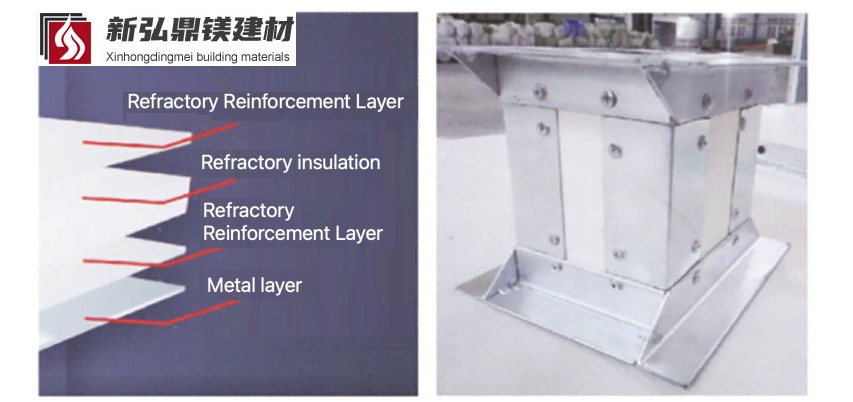

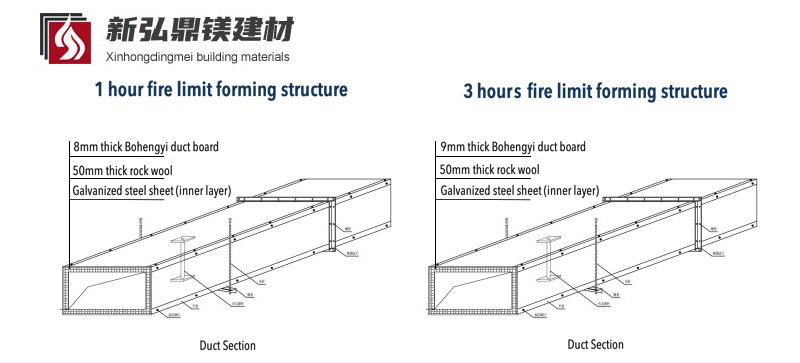

The refractory clad metal air duct is filled with 50mm rock wool on the outer surface of the original metal air duct,

and covered with 8mm or 9mm Bohengyi air duct plate. It meets the requirements for the fire resistance limit of ventilation

ducts in GB51251-2017 "Technical Standards for Smoke Prevention and Exhaust Systems in Buildings".

Combustion performance A1 grade, high strength and light weight, water and moisture resistance, easy processing".

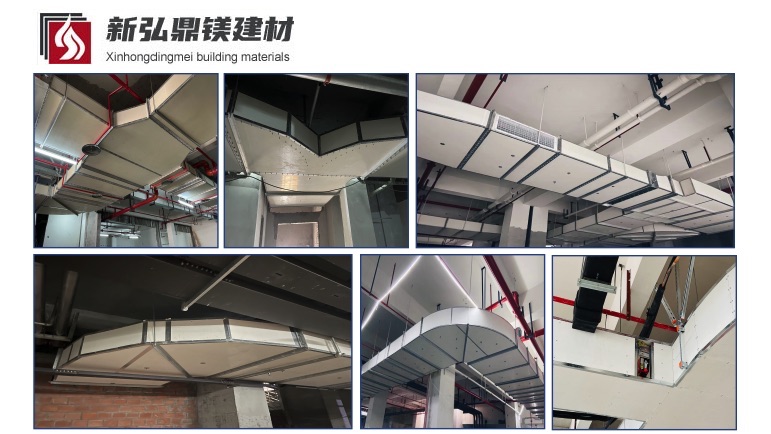

Widely used in smoke prevention and exhaust systems of various buildings.